- Home

- Foreword

- Contents

- 1. Retrospective and perspectives

- 2. At the heart of safety: high standards and leadership

- 3. Industrial safety and radiological protection: it’s behaviours that count

- 4. Pragmatism for the EPR2

- 5. The fleet upgrade: a colossal programme

- 6. Reactors that adapt to climate change

- 7. Nuclear fuel and reactivity control: the heart of nuclear safety

- 8. Competences: are we sufficiently demanding?

- 9. Changes in the electricity system: anticipate rather than suffer

- Appendices

- Contact

Navigation

Navigation

INTRODUCTION

The EPR2 is an optimised and standardised version of the EPR. Its design incorporates nuclear safety and environmental standards considered to be among the best in the world.

The current EPR2 programme includes the construction of three pairs of reactors with the option of building four additional pairs.

The first three sites allocated for these projects are Penly, Gravelines and Bugey.

The EPR2 project has been strengthened since the French President’s speech at Belfort in February 2022, and benefits from the Act of June 2023 relating to the acceleration of construction procedures for nuclear new-build. An inter-ministerial delegation for nuclear new- build projects (DINN) is supervising the programme and coordinating the administrative process. These governmental measures and the Group’s reorganisation reflect the desire to provide the right conditions for the success of the EPR2 programme.

To complete this healthy dynamic, the timetables for the regulatory review by the French nuclear safety authority (ASN) and for EDF’s project must be aligned. The acceleration of the programme will be sustained and will require all stakeholders to work in project mode.

2023: A TRANSITIONAL YEAR

The project’s governance is well organised. The project owner’s design reviews, combined with maturity reviews, open-point steering committees, and modifications committees, all strengthen the project. The technical authority, which should soon be created within the STID (Strategy, Technologies, Innovations and Development), will provide a cross-functional and strategic vision of some nuclear safety subjects, thus ensuring standardisation for replication of the first reactor series.

I commend the programme review organised between the DINN and EDF. Its report assesses the maturity of the EPR2 at the end of the basic design, the conditions for starting the detailed design, and the coherence of both the schedule and the costs. Other than providing a current status, this review makes recommendations on the organisational aspects, design, industrial method, relations with the authorities, partnerships with suppliers, project deadlines, and performance.

The teams at Edvance in charge of the detailed design are rapidly growing in size, with the key issues being the development of competences and the on-boarding of new staff. Guidance from the Operator will be necessary to ensure the plant is adapted to their needs, particularly in terms of equipment layout, definition of the general operating rules (RGE), and design of the human-machine interface. I am pleased to note that the Industrial Division (DI) is fully involved and accountable for the choice of materials.

The DINN - an inter-ministerial delegation for nuclear new-build projects

Created by the ministerial decree of 7 November 2022 and in line with the French President’s energy speech in Belfort, the DINN is tasked with supervising the industrial construction programmes for the new nuclear power reactors in France. Reporting to the Prime Minister, it ensures that these programmes are executed within the defined deadlines and budgets. It will contribute to the implementation of measures under the government’s responsibility and coordinate all stakeholders.

The project was relocated to Lyon in the summer of 2023 in preparation for the expansion of its teams. The staff remaining in the Paris region has been reassigned to other engineering units in the capital and continue to work for the project.

The Engineering & New Nuclear Projects Directorate (DIPNN) is resolving difficulties related to its new digital environment, i.e. the 3DX plant lifecycle management (PLM) software. The under-performing documentation and piping & instrumentation diagram (P&ID) modules have led to a loss in productivity. The technical teams should have been more involved with the developers during the software development phase. Data from the Gravelines site could still not be replicated in 3DX and will have to be verified.

The industrial success of the EPR2 project will depend on our ability to ‘get things right first time’ by replication. The series effect needs to be strictly maintained on the first six reactors so the next reactors can benefit as much as possible from optimised quality, timescale and cost factors.

The ASN and EDF have agreed that the generic sections of the nuclear safety report for the Penly reactors, and its conclusions, will apply to the entire first EPR2 series. It is essential that this principle be respected over time, and it deserves to be extended to cover nuclear pressure equipment (ESPN) regulations for the manufacturing of large components and standardised equipment. Before starting the detailed design activities, the requirements and standards applicable in the fields of fire, seismic and aircraft crashes must be agreed with the ASN and the Senior Defence & Security Official.

Authorisations needed before construction

In February 2022, EDF requested the French national public debate commission (CDNP) to organise a public consultation from October 2022 to February 2023 on the construction programme for the reactor series. This commission published its report in April 2023.

The EDF project owner confirmed on 28 June 2023 that the project would continue.

Before construction can start, two authorisations must be obtained: a concession to use the public maritime domain (CUDPM) and an environmental authorisation (DDAE). The requests have been submitted, which will require a public enquiry.

A request for a licensing application (DAC) has also been submitted. The DAC must be obtained before construction of the nuclear structures can begin.

DEVELOPING A FIRST-CLASS SUPPLY CHAIN

The success of the EPR2 project does not lie in sophisticated design studies, which can lead to a complex design, but in our capacity to build a robust supply chain that can deliver products of the highest quality.

The industrial policy and choice of suppliers are managed with an integrated approach that includes a suppliers’ committee which meets every week. Its effectiveness is recognised by all. The Supplier Development initiative underpins this approach by supporting the development of competences and supplier quality.

Framatome will have to invest in its industrial facilities. A factories think-tank will be launched in 2024 to define the strategy and more specifically organise the factories based on a series production flow of all large components for the nuclear steam supply systems (NSSS). The forging of the first components has been completed. The manufacturing quality and inspections have progressed over the past few years. ASN and customer confidence levels have been consolidated. Standardised manufacturing will call for a learning- based approach to continue to improve the processes and to gradually reduce the need for quality exemptions.

The regulatory process for issuing compliance certificates for ESPN will have to be adapted. This process was completed too late for the Flamanville 3 project, after installation of all the equipment, which will continue to be an industrial risk right up to fuel loading.

The division responsible for equipment manages the equipment lifecycle, which involves relationships with the industrial partners, monitoring manufacturing, delivery, assembly and testing. The majority of the contracts were awarded in 2023, and this process will continue in 2024 well in advance of the project. This is a positive point, which gives the supply chain greater visibility. This early planning will make it possible to engage suppliers in the engineering process to ensure that industrial solutions are chosen in alignment with current standards.

Equipment manufacturers will mainly be French or European companies. The replication rate of equipment at Flamanville 3 will finally be lower than hoped, due to different technical specifications between the projects, and a supply chain that evolved over 20 years.

CONTINUE INCREASING OPERATOR INVOLVEMENT

Although the Operator has been involved in the project since 2017, their requirements came too late for all of them to be fully taken into account. Their involvement has been consolidated in the project and with the project owner. Reviews co-chaired with DPN management have been influencing choices. The Operator is involved in the contract award phase.

The performance of the EPR2, in particular its availability, must meet international standards. To achieve this level of performance from the first-in-the-series, the general operating rules (RGE) must guarantee not only nuclear safety but also generation. I will follow the approaches that have been initiated to simplify these rules (see Chapter 2).

Preliminary work on the choice of equipment maintenance (condition- based or standard exchange, etc.) has already been completed. This work must be continued. Moreover, I consider it necessary to incorporate the possibility of replacing large components like steam generators on an industrial scale. The design of the human-machine interface must take into account operations and benefit from the R&D work on modelling and imaging of thermohydraulic phenomena.

The operating choices for the EPR2 must be based on the best organisational practices: shift rotas, control room operator teams organised to allow for just-in-time training (including a pre-shift cycle training day), dedicated teams for shutdowns, and work execution centres (WEC) need to be taken into account.

The fuel chosen for the EPR2 must be consistent with the standards of the EDF fleet for 2035 (see Chapter 7).

The EPR2

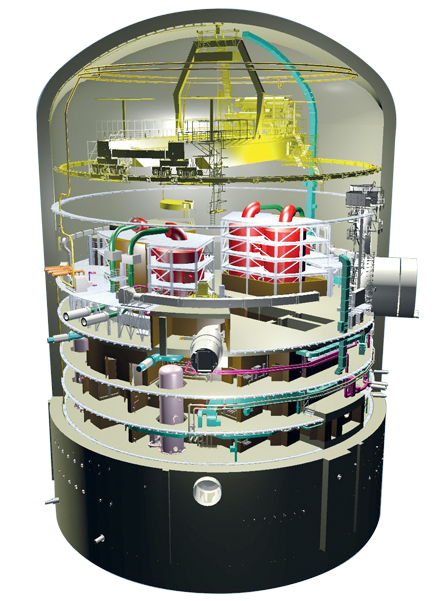

The EPR2 boasts the same power output (1670 MWe), the same high level of nuclear safety, and the same main equipment and systems as the EPR, which are strengths for managing the industrial risks. It incorporates operating experience from all the EPR construction sites in the world, and that of the current operating fleet.

Adopting the main characteristics of the EPR (aircraft-impact-resistant shell, corium catcher, hydrogen recombiners, diversified onsite back-up power supplies, etc.), the EPR2 differs by its single reactor containment, three safety trains, and a diversified heat sink.

It is designed to be able to load-follow as per the Operator’s requirements. The EPR2 takes account of climate change and will be able to adapt to it.

DESIGN MARGINS TO ALLOW FOR 60 YEARS OF OPERATION

The EPR2 design margins must be robust enough to cover operation for at least 60 years. Its design must also be adaptable over time.

The project’s management team has set up an ad hoc steering committee for design margins. I would like to stress the merits of this initiative, which should be maintained over time, from design through to full commercial operation.

Climate change is integrated into the design. The EPR2 has been designed to very conservative assumptions. The applicable standards are demanding and include margins. To avoid an overly complex or oversized design, the excessive accumulation of conservatisms must be avoided, especially where operating contingencies would be sufficient (see Chapter 6).

I take note of the good direction in which the technical discussions are heading with the ASN on the break preclusion safety case. The project is drawing lessons from the stress corrosion cracking (SCC) issue. Specific measures are being defined in line with suitable installation methods and inspection programmes. Pipework routing will be reviewed. Welding processes, assembly dimensional tolerances, weld preparation, maximising prefabricated sections, and minimisation of the number of site welds: these are all favourable factors that help prevent SCC. Knowledge about the origins of this unprecedented phenomenon is likely to increase, and the project will need to keep a watchful eye on it to incorporate any lessons learned.

From as early as the design studies phase, the EPR2 should benefit from the new reactor physics calculation platform ODYSSEE. More predictive than current tools, it benefits from the latest modelling advances.

OTHER PROJECTS: FLA3, HPC AND SZC

Flamanville 3 on the final straight

The repairs to welds on the secondary system pipes of the Flamanville 3 EPR (FLA3), their stress-relieving treatment and the related hydraulic tests were finally completed in summer 2023. These activities have punctuated four years of work. The full system requalification tests (ERE 23) were successfully completed on 10 December 2023. However, the schedule of activities to complete before fuel loading is tight and remains conditioned by the outstanding work to be processed and the regulatory authorisations to be obtained.

The technical discussions with the ASN are running smoothly. Workarounds to resolve reliability issues with in-reactor instrumentation and neutron flux variations have been defined for the first years of operation.

FLA3

Long-term solutions will be implemented once the analyses and test programmes have been completed. Our understanding of the accelerated corrosion of M5 alloy used in fuel assemblies must continue to progress. Prevention measures have been defined (see Chapter 7).

I support the initiative of an internal authorisation system (SAI) based on that used for core-fuel issues and approved by the ASN to authorise progression through the different intermediate power levels of the start-up phase.

The first full inspection outage programme remains colossal. To prepare for it, specific, dedicated resources must now be provided and protected from unplanned activities, which are inherent to the start-up phase and the first operating cycle.

Experience that must be exploited by other projects

A wealth of experience has been gained from the FLA3 project. The EPR2 project, which is entering its detailed design phase, must take full advantage of this. The practices relating to the operations organisation, resource requirements, the necessary flexibility of relations with Framatome, procurement of spare parts, choice of human-machine interface, layout of equipment, reliability of ventilation equipment and electrical cubicles, and integration of support systems for the main diesel generators: these all need to be analysed in depth. Strengthened by this invaluable knowledge, key players from the FLA3 project must be able to devote some of their time to the EPR2 project to ensure the transfer of their field experience.

As mentioned in the 2022 report, the Hinkley Point C project (HPC) must seize the chance to take part in the start-up phase of FLA3. The teams on site are ready. This investment will be profitable.

The Operator’s link with the construction, assembly and test teams on the future French and British projects must take inspiration from the ONE Fla3 approach. Although late to start, this approach has had the advantage of bringing together all the players to focus on a common goal by consolidating the position of the future owner-operator. The handover processes (for plant isolation, maintenance and operation of equipment, systems and rooms) used at FLA3 were the same as those used during the start-ups of previous reactor series. This operating experience must be exploited on the EPR2 project.

On the construction sites of new reactors, before classification as a nuclear plant, I believe it is essential to pay greater attention, and as early as the construction phase, to the protection of industrial assets from fire, which was not the case for FLA3.

Penly: the first EPR2 site

The Penly site will soon host four high-power reactors: two 1300 MWe already in service, and two new EPR2s.

The EPR2 project is benefiting from the support of the regional authorities. It minimises its footprint on both the land and maritime biodiversity by building on an already developed site and an optimised siting impact. It meets the ten technical criteria recommended by the IAEA: siting, urban planning, heat sink, soil types, external risks such as earthquakes and flooding, environmental sensitivity including discharges from an industrial facility, location and connection to the electric grid.

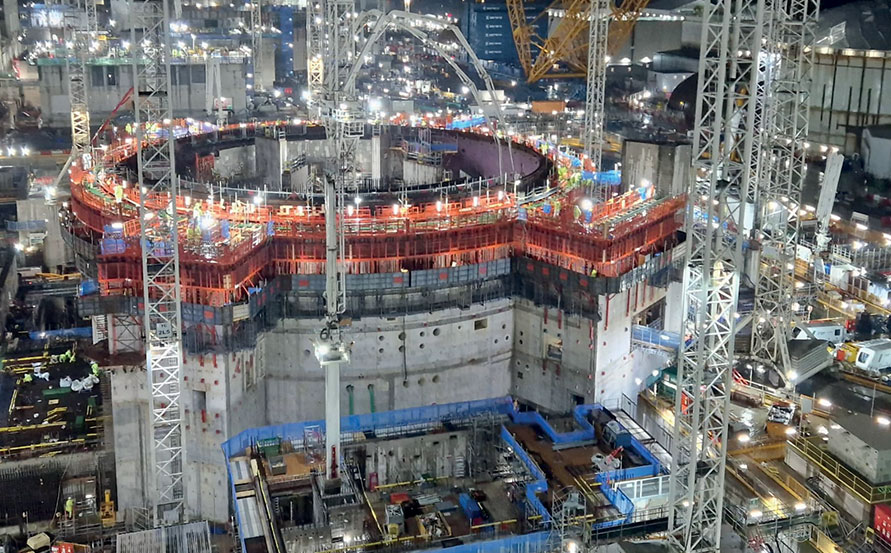

HPC: the start of MEH installation

In the UK, an important milestone was achieved when the dome of reactor 1 was installed on 15 December 2023 for the EPR at Hinkley Point C (HPC). The project will turn a new page in 2024 when the mechanical, electrical and HVAC (MEH) work will accelerate, calling for good coordination and high-quality installation. The types of industrial safety risks will change with the increasing number of activities carried out simultaneously on the site (see Chapter 3). The project will have to coordinate the assembly of the first pipes, procurement of which has experienced some delay. It will also have to establish a strong link between productivity (mass-installation) and management by milestones in relation to the civil engineering work. The work schedules, which are very ambitious compared with previous construction sites, must be achieved without compromising quality.

Compared with the other EPR projects, HPC has a good degree of design maturity for the MEH aspect. In mid-2023, 90% of the detailed design was available and enabled the production of the installation drawings. I note that the quality control process for the equipment is robust. However, the project is still waiting on some suppliers to finish the detailed design and installation drawings. The equipment qualification programme entrusted to some suppliers also requires particular attention.

Dome lift Video

The strategy for the establishment of the commissioning teams is well aligned, ensuring that the future Operator benefits from acquired experience. The level of recruitment and staffing of the maintenance teams seems insufficient and needs careful attention, with the latter currently being equal to that of FLA3 even though the site will host two new reactors and 20% more equipment per reactor. Conscious of this problem, the HPC project is working on a reassessment of the maintenance staffing target by performing a comparison with those of Sizewell B, OL3 and FLA3.

The experience from the HPC project must benefit the EPR2 project in all areas: design, civil engineering construction methods, mechanical and electrical installation, supply chain, commissioning know-how, operating model, planning methods, management tools, etc.

Sizewell C: replicating HPC

The Sizewell C EPR project is resolutely driven towards the replication of HPC. This choice must be maintained over time. The Office for Nuclear Regulation (ONR) officially supports this principle, which is key to efficiency, quality and thus nuclear safety. Replication involves the transfer of the detailed design and the construction drawings. As a result of the differing ownership models and corporate cultures, the risk of design deviations must be monitored for the duration of the project. The environment, geology, and the site layout plan associated with the specific features and close proximity of the Sizewell B PWR entail changes that must not challenge the principle of replication. Regulatory changes in the fields of fire safety and ALARA will call for substantiation reports. Lastly, the acceleration of the construction schedule must not lead to choosing options that call the design into question.

RECOMMENDATIONS

To ensure that the EPR2 design remains as safe and simple as possible, I recommend that the Director of the DIPNN, in liaison with the ASN, take measures to prevent excessive design conservatisms and operational countermeasures.

To fully benefit from the operating experience of both the in-service fleet and the EPR projects, I recommend that the Directors of the DPNT and the DIPNN further involve the Operator in the engineering teams responsible for the detailed design of the EPR2.

RECOMMENDATIONS |

To ensure that the EPR2 design remains as safe and simple as possible, I recommend that the Director of the DIPNN, in liaison with the ASN, take measures to prevent excessive design conservatisms and operational countermeasures.

To fully benefit from the operating experience of both the in-service fleet and the EPR projects, I recommend that the Directors of the DPNT and the DIPNN further involve the Operator in the engineering teams responsible for the detailed design of the EPR2.