- Home

- Foreword

- Contents

- 1. Retrospective and perspectives

- 2. At the heart of safety: high standards and leadership

- 3. Industrial safety and radiological protection: it’s behaviours that count

- 4. Pragmatism for the EPR2

- 5. The fleet upgrade: a colossal programme

- 6. Reactors that adapt to climate change

- 7. Nuclear fuel and reactivity control: the heart of nuclear safety

- 8. Competences: are we sufficiently demanding?

- 9. Changes in the electricity system: anticipate rather than suffer

- Appendices

- Contact

Navigation

Navigation

* “The Grand Carénage is a heavy worload! I agree” © Nicolas Waeckel

INTRODUCTION

The 56 reactors comprising the French fleet do not have a technical or regulatory age limit.

An upgrade programme (Grand Carénage) was initiated in 2015. The purpose of this vast financial and human investment is to extend the service lives of reactors in operation beyond 40 years.

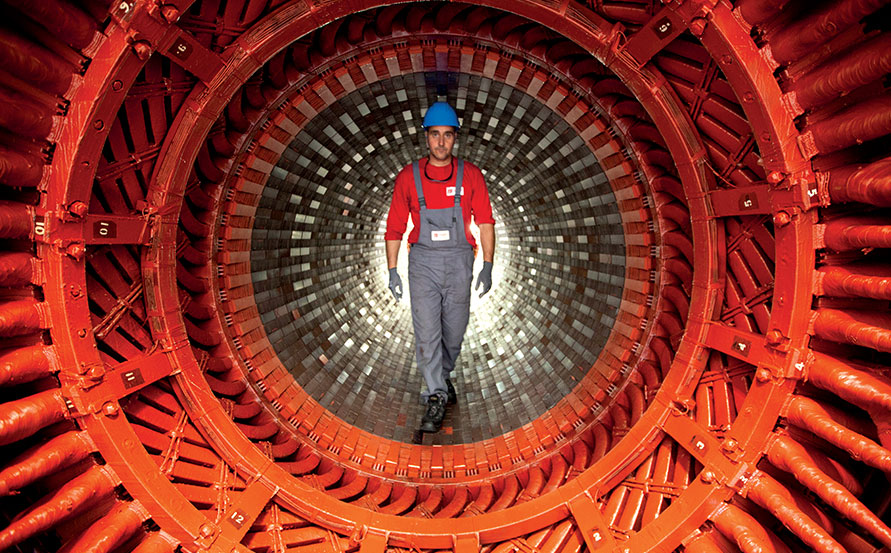

In the UK, Sizewell B has started its ‘Long-Term Operation’ programme to extend this reactor’s service life at least up to 2055.

The EDF Group launched a vast investment programme to extend the service life of its operational fleet beyond 40 years, with the goal of becoming a global reference in nuclear safety. This programme is exceptional due to the volume and complexity of the works involved, which is spread over more than a decade. It mobilises the sites, engineering departments and all of its industrial partners. The modifications are carried out during the fourth ten-yearly outages (VD4) of each reactor of the 900 and 1300 MWe series, and during the third ten yearly outages for the 1450 MWe series.

In a similar manner, EDF Energy launched its Long-Term Operation (LTO) for the Sizewell B PWR, planning for its operation up to at least 2055.

Framatome has carried out significant investment to refurbish its fuel fabrication plant at Romans-sur-Isère.

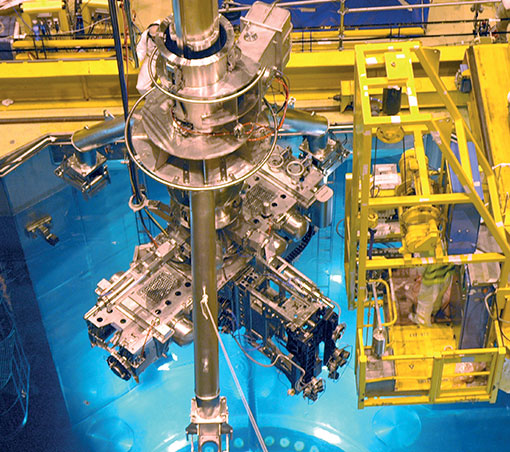

In France, the service life of a nuclear reactor is not defined in advance. The Operator performs a periodic safety review (RP) every ten years to confirm the plant’s compliance with the applicable rules and to update the nuclear safety risk assessment. The safety review takes into account the plant’s condition, experience collected during operation, technological advances, standards and knowledge, including those concerning climate change and its effects. 60% of the modifications are completed during the ten-yearly outages (VD). To even out the workload of the VD4s, additional suites of modifications supporting the initial modifications are programmed during the following outages.

THE FLEET UPGRADE PROGRAMME LEADS THE WAY

This fleet upgrade (GK) programme is working towards three objectives:

- Extend reactor service lives by guaranteeing their compliance with the applicable standards and carrying out modifications to consolidate their nuclear safety.

- Enable the in-service fleet to reach its generation targets without compromising nuclear safety.

- Safeguard and optimise the financial trajectory of its investments.

The GK programme has succeeded in bringing together all the stakeholders around the modular outage preparation process. The ultimate emergency diesel generators (DUS) have been installed and the deployment of the emergency water sources is in its final phase on each site. Despite the disruption of the Covid pandemic, followed by the stress corrosion cracking issue, the GK programme has remained on plan.

Although the results are very positive, the workload continues to intensify. The modification documentation for the first reactors has not been delivered in compliance with the modular outage preparation milestones. The replacements of the last steam generators were poorly managed: Framatome and the project directorate have implemented an action plan to bring this activity under control. The next steam generator replacements must have a reliable schedule, worksite competences at all sub-contracting levels, and a robust organisation during both preparation and implementation.

Progress still needs to be made on the availability of spare parts and the updating of documents and databases for the first-in-series sites. Training specific to each modification is still not fully integrated and is not providing Operators with an overall view. Operating experience of the modifications must also be improved.

The GK programme has included a significant amount of asset investment, fundamental to ensuring plant life extensions. It is important that such investments be continued.

THE 900 VD4S RICH IN LEARNING

Success of the 900 VD4 project

The fourth periodic safety review (RP4) of the 32 reactors comprising the 900 MWe series led to an unprecedented programme of plant modifications. The workload is five times greater than that of the VD3s. Consolidation of defence-in-depth, which includes the post-Fukushima Daiichi ultimate emergency equipment, represents a significant advance for nuclear safety. The first-in-series VD4 of the CPY series (28 reactors) at Tricastin was completed successfully in 2019. Bugey, with its specificities of the CP0 series, has successfully incorporated operating experience from its first VD4. The VD4s for the 900 MWe plants are still being rolled out without an outbreak of significant events.

VD4 Gravelinnes

Lessons learned from the RP4 900

Beyond the successes of the VD4 900 project, lessons must be learned for the other periodic safety reviews. These reviews started late for the 900 MWe series. The organisations had to be adapted to meet the deadlines for the first-in-series. The modification documents were delivered late. The very significant modification programme required integration in three phases. Between two ten-yearly outages, the teams live with constant changes to equipment and operating standards. These conditions do not give teams time to assimilate their plant, and organisations end up being saturated. The RP4 900 generated numerous technical prescriptions which could not be prepared for due to their late inclusion. Some modifications relating to the tornado risk have to be updated every few years to integrate new standards.

Points of attention

The VD4 900 project must now overcome several issues. In the context of a very heavy workload, the rate of implementation must be maintained across all the plants. The quality of work must not be compromised by the sustained pace of equipment delivery and the involvement of new contractors. It is also important to know how to close-out the project by rejecting modifications that may come to light too late.

I commend the initiatives from the Nuclear Fleet Engineering, Decommissioning & Environment Division (DIPDE) to improve its work methods, like the standardisation of modification documents through the ‘NOM’ING’ project and the development of a hybrid digital mock- up. This should not, however, replace the presence of teams on site.

In preparation for outages, 70% of the modifications are carried out with the reactor in service, which makes operations complex and increases the workload of control room operators, especially in terms of managing the many inhibited fire detectors, negatively affecting control room serenity. The number of exemptions from the technical specifications has increased. The activity schedules have become denser, and their reliability has deteriorated. The accumulation of limiting conditions complicates the planning of the instrumentation technician’s activities, who must carry out routine activities outside normal working hours. I expect that the findings of the organisational and human factors study carried out at Tricastin will be taken into account.

The transition to the VD4 operating standards is not without impact on the fuel loading plans. The fuel reloading safety assessments require significantly more powerful calculation means and, in 25% of cases, the fuel loading plans have to be re-modelled (see Chapter 7).

Hybrid digital mock-up (MNH)

The MNH is a user-friendly digital tool that provides 3D layout drawings. It combines 3D scans of facilities with photos to create layout drawings in 3D with an accuracy of a tenth of a millimetre. It is available for each first-in- series for the CP0, CPY, P4, and P’4 series and is in the process of being developed for the N4 series. Used to support site surveys, it helps the DIPDE, the Electromechanical & Plant Engineering Support Department (CNEPE) and their partner design offices during the development phase of modifications. The Operations & Engineering Training Department (UFPI) and the plant Operators also use the MNH.

DRAWING LESSONS FROM RP4 900 FOR RP4 1300 AND RP3 N4

RP4 1 300, une charge de travail inédite

The fourth periodic safety reviews (RP4) of the 1300 MWe reactor series set out to improve nuclear safety to levels at least equivalent to those of the RP4 900. EDF has been better prepared for the VD4 1300 than that of the VD4 900 whose programme was affected by the lessons learned from the Fukushima Daiichi accident.

The first year of implementation (2026) will be exceptionally busy. EDF is faced with an unprecedented task, with the implementation covering 25% of the 1300 MWe series in two years, whereas for the 900 MWe CPY series, a gap of more than one year was programmed between the VD4 of the first-in-series (Tricastin 1) and that of the second reactor (Dampierre 1). A specific organisation will have to be set up to capitalise on the operating experience collected from the first outages. The workload is phenomenal at Paluel, where two VD4s will be completed in 18 months, including the first-in-series, a steam generator replacement, and the replacement of primary system pipework bends. Saint Alban is also preparing to start its vast industrial programme. From 2027 to 2029, the site will carry out two ten-yearly inspection outages, one steam generator replacement, as well as the first-in-series second modification phase (Lot B). Although all the organisational measures seem to be in place, these sites could find themselves in difficulty; and I suggest strengthening the support planned for this plant.

Consolidated project governance

The governance of plant safety reviews has been organised between EDF and the nuclear safety authority (ASN) since 2021. Operating experience from the RP4 of the 900 MWe series has been put to good use. Modifications will be limited to two phases rather than three, and documentary changes will be based on phases rather than on schedule deadlines. The scope of the first phase of modifications was validated by the ASN in the summer of 2023. I believe that the volume of the second work package should be contained, and that modifications providing very little improvement to nuclear safety should be avoided. The general opinion of the ASN on the VD4 1300 project will be available six months before starting the first-in-series at Paluel, whereas it was only made available after the VD4 at Tricastin, the first- in-series of the 900 MWe series.

In the interests of efficiency, the project engages the sites from the start of design to direct the best technical choices. Collaborative working centres bring together the DIPDE engineering staff and the three first- in-series sites (Paluel, Cattenom and Saint Alban). These centres are already working well. A weekly meeting every Thursday complements the work centre approach, monitors the progress of the project, and provides a global overview that is appreciated by all.

Nevertheless, the first modification documents will be delivered very shortly before the start of the first-in-series outages. To remedy this delay, the sites will have no other choice than to reinforce the preparation for the outages and the coordination of activities that will be performed when the reactor is in service. The DIPDE support for the first-in-series sites will have to be adapted accordingly and take into account the geographical remoteness.

Project challenges

The EDF Group’s engineering teams (DIPDE, CNEPE and DT) have multiple challenges to overcome. It is important to keep in mind the notion of “strictly necessary”. I must repeat my recommendation from 2022 for the need to reduce, with the ASN, the list of modifications proposed for the 1300 MWe VD4 series and the N4 VD3 series, in view of the expected nuclear safety benefits. The studies will have to be tightly managed to meet the deadlines. Workarounds will have to be found to compensate for the engineering resources that could not be reassigned from the VD4 900 project to the VD4 1300 project as a result of a very heavy workload. The technical specifications for industrial partners will have to be issued as soon as possible so they can be engaged in the engineering process. The industrial partners could also help define technical solutions and plan ahead for the procurement of long lead-time components for the circuits and cabling. Lastly, the multiple levels of sub-contracting must be closely monitored in terms of quality and deadlines for equipment deliveries.

Reactor unit compliance review (ECOT)

These compliance reviews help to show that the reactor conditions correspond to their reference state. This is demonstrated through specific in situ inspections of structures and equipment, as well as the verification that the applicable standards are being deployed in the plant. Methodical and selective, this approach relies on the incorporation of regulatory requirements into the site’s standards and operating documents, and on representative sampling campaigns. The objective is to allow the Operator to engage in the compliance of their plant and to formalise this engagement through tangible and verifiable information.

Forward planning for the VD3 N4

The project for the VD3 N4 series was launched in 2021 with an alignment logic of ‘4-4-3’ with the VD4 900 projects and the VD4 1300 projects. The N4 series will benefit from the latest advances in nuclear safety as early as its VD3, without having to wait for its fourth periodic safety review. The first-in-series at Chooz is scheduled for 2029 and will take into account the modifications of the 1300 MWe series, which are taken as the reference. The power output of the ultimate emergency diesel generators warrants special attention.

PLANT SERVICE LIFE, FOCUS ON CLIMATE CHANGE

The modifications of the last ten-yearly outages are part of an incremental approach to improving the safety of our facilities, with a very significant increase in the VD4 project to bring them closer to the highest standards of the EPR. Focus will now have to turn to operational quality levels and asset investment. The scope of the fifth ten-yearly outages (VD5) will have to be limited to compliance assessment and climate change (see Chapter 6). Ensuring plant equipment qualification for accident conditions for extension to 50 years will mainly relate to electrical equipment, for which the necessary means will have to be allocated. The VD5 project must be rapidly provided with resources and competences.

The technical issues associated with extending plant service lives mainly concern the reactor vessels, the cast bends on the primary cooling systems, and the reactor containments. I am pleased to see that the carbon segregation safety study is in the final stages of resolution. I also commend the joint initiative between the ASN and EDF to bring forward the review of plant life horizons for the reactors in service.

Four reactor vessels from the 900 MWe series require specific substantiation measures. The reactor containments on three sites (two 1300 MWe and one N4) warrant a specific treatment. Alternative solutions to calculation-based substantiation are being investigated for the cast bends on primary cooling systems. The specific seismic risk at the Cruas site (following the Teil earthquake) will have to be analysed pragmatically, taking care to cover the most extreme scenarios using suitable methods.

In 2019, EDF R&D initiated an approach to identify the technical obstacles for operation in the long-term. More specifically, comparisons have been made with the US who have already granted operating licence extensions up to 80 years, with 60 years being granted for those reactors that applied for it. This initiative tends to encourage a more asset-based approach, rather than a regulatory one. For instance, work on mechanical analysis methods has begun at EDF R&D to determine the margins for reactor vessel service lives using state-of-the-art digital analysis methods. A modification making it possible to heat the safety injection system water would also free up margins in the field of brittle fracture of reactor vessels.

Comparison with international practices must also help to find realistic solutions. In September 2023, EDF organised a symposium on the subject of plant service life extensions with the world’s main nuclear players. They did not identify any obstacles that would prevent the industry from going ahead with plant life extensions beyond 60 years. In France, our methods are extremely conservative in comparison with international practices.

In addition, in light of operating experience, the exploratory inspection programme needs adapting to monitor the behaviour of materials and equipment in certain areas where defects are not expected to occur.

Vercors: a reactor building mock-up

Vercors is a mock-up of a P4-type reactor building at a one-third scale. This mock-up is used to predict changes (creep, propagation of defects, and water diffusion in concrete) in a reactor building representative of EDF reactors. Time is accelerated by a factor of 9.

The Vercors facility currently represents a 70-year-old reactor building. The leak rate criteria of the reactor containment remain compliant. Changes in its dimensions and leak rate seem to be stabilising over time. No specific weaknesses have been detected, whether in the pre-stressing or due to the appearance of specific leakage areas such as the basemat, the top ring, penetrations or equipment hatch.

FOSTERING A ‘STRICTLY NECESSARY’ CULTURE

Faced with the tremendous volume of work, the engineering teams for the operational fleet (DIPDE) have been growing in size every year and sub-contract more work than they are accustomed to in order to keep pace. Overly detailed and prescriptive, the standards applicable to plant modifications are too restrictive. The minimum period for deployment of modifications is three years between the approval to proceed based on a basic design and the first implementation. This deadline puts a strain on already tight schedules.

The workload is constantly growing. The VD4 900 projects are in full swing, with a volume of activity that is decreasing more slowly than expected due to the additional work phases (lot B and lot B+). For the 1300 MWe series, even though the RP3 safety reviews have yet to be definitively closed out, the engineering programme for the fourth periodic reviews (RP4) has already been launched at full speed with modifications to be deployed from 2026. The RP3 for the 1450 MWe series and the RP5 for the 900 MWe series will soon be added. This stacking effect must be brought under control to ensure that the workload is sustainable for all stakeholders: EDF engineering, the Operator, industrial partners, the ASN and IRSN. In line with my recommendation from 2022, I advocate the development, in conjunction with the ASN, of a ‘strictly necessary’ culture, and the use of a method of ‘weighting’ safety challenges to enable prioritisation of the modifications, as well as foregoing those that contribute very little to nuclear safety margins.

François Roussely predicted as early as 2010 that “the only reasonable logic cannot be a continuous increase in safety standards […]”, and it was necessary to “combine safety standards and economic constraints as effectively as possible, including an international or at least European vision”.

The industrial programme for the in-service sites has intensified significantly these past few years. The volume of work of the RP4 with its cavalcade of modifications has distanced us from the historical approach of ‘leaping from one 10-yearly outage to the next’, moving instead towards a continuous stream of modifications. Sites with four or six 900 MWe reactors are constantly completing modification after modification, without being able to achieve any stability before starting the RP5. Added to this are the Covid pandemic and the stress corrosion cracking issue. The outage placement programme has reached a level of instability too great for the smooth implementation of an industrial programme of this scale. The context has become so complex that a simple refuelling outage (offering a break in maintenance activities) on a reactor with an 18-month fuel cycle can no longer be scheduled.

I commend the joint initiatives supported by EDF and the ASN to better manage and lighten the workload of periodic safety reviews. A multi- year outlook makes it easier to identify periods with high volumes of work. Ownership between EDF and the ASN will help to moderate and make progress on safety studies. Finally, a ‘workload management’ working group has enabled optimisation of the assessment process for certain requests from the ASN. For the RP4 1300, EDF has also suggested simplifying the assessment of modification studies in a way similar to the method used for the 900 MWe series, working on the basis of expert opinions and the transposition of studies already carried out.

SIZEWELL B: ON COURSE FOR 60+ YEARS

The Sizewell B pressurised water reactor, EDF Energy’s flagship plant, was commissioned in 1995. It benefits from a very robust design. Some of the safety case studies justified an operating life of 40 years, which is why the site has launched its Long-Term Operation (LTO) programme. Investment will be spread over a ten-year period with the objective of achieving 60 years of operation or more. In the US, the Callaway and Wolf Creek sites (sister plants to Sizewell B) have already been granted a licence extension to operate for 60 years.

Sizewell B has organised the LTO project with the support of Nuclear Operations and is currently in the process of defining its scope. I will make sure the financing arrangements do not influence the nuclear safety decisions or impact their correct implementation. I noted that the British nuclear safety authority (ONR) was included in the definition phase of the programme. Securing the resources and competences to successfully implement this programme represents a major challenge. A specific delivery organisation has been created, and engineering recruitment has been launched by the site and by the Joint Technical Organisation. The main challenge is to ensure that the site, the corporate teams and the industrial partners have the capacity to meet the milestones. I commend the initiative to schedule an International Atomic Energy Agency (IAEA) review mission by 2030, known as SALTO, to support the site’s approach.

As neighbours, the Sizewell B and C sites share the same nuclear safety issues so their methods of treating them will have to be coherent. The risk of turbine blade ejection and flooding assumptions should be worked on together.

The end-of-life dates for the AGR fleet remain the same, except for Heysham 1 and Hartlepool, which are now scheduled for final shutdown in 2026 plus or minus a year. The investment programme for these two sites has subsequently been revised and must now be implemented.

Heysham 1 Forty years

SALTO

The IAEA offers its Member States review missions on the safety aspects of long-term operation (SALTO): a comprehensive safety review directly addressing strategy and key elements for the safe long-term operation of nuclear power plants. The evaluation of programmes and performance is made on the basis of the IAEA’s Safety Standards and other guidance documents. These reviews are led by peers who check compliance and issue recommendations for improvements where necessary. These reviews enable plant staff to share their work practices with experts; they strengthen the public’s confidence, and provide assistance for licence renewals and plant life extension requests.

THIRD PERIODIC SAFETY REVIEW FOR ROMANS-SUR-ISÈRE

The fuel fabrication plant at Romans-sur-Isère submitted its third periodic safety review to the ASN in 2023. The workload that will result from this review and the ongoing resolution of non-conformities will have to be finished by late 2025.

The main plant upgrades have already been done within the scope of the previous periodic review and the post-Fukushima Daiichi re- evaluation. They led to the creation of new fuel fabrication facilities for research reactors, which will be commissioned some time in 2024.

Considering the nature of the industrial activities carried out on site, its geographic location and investments already allocated, the effects of climate change should not lead to new modifications in the next few years.

RECOMMENDATION

The stability of work programmes is a prerequisite for the success of the RP4 1300 and RP5 900 periodic safety reviews, I recommend that the directors of the DPNT and the DIPNN work with the ASN to define the assessment process for managing the different phases of the periodic safety review, including by freezing the assumptions and methods, at the latest by the review of the design assumptions.

RECOMMENDATION |

The stability of work programmes is a prerequisite for the success of the RP4 1300 and RP5 900 periodic safety reviews, I recommend that the directors of the DPNT and the DIPNN work with the ASN to define the assessment process for managing the different phases of the periodic safety review, including by freezing the assumptions and methods, at the latest by the review of the design assumptions.